| 【R2R demo machine】 | ||

|---|---|---|

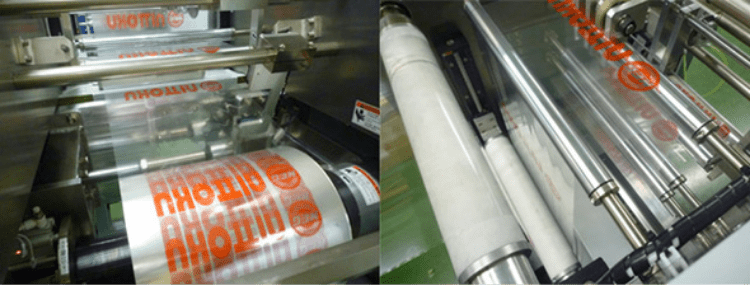

| Base material specification | Base material | PET, PI, PP, PEN, Cu, SUS, non-woven |

| Substrate thickness | ~ 150μm | |

| Substrate width | ~ 600mm | |

| Material specification | Material (core) inner diameter | φ3inch |

| Material outer diameter | ~ Φ400mm | |

| Material weight | ~ 100kg | |

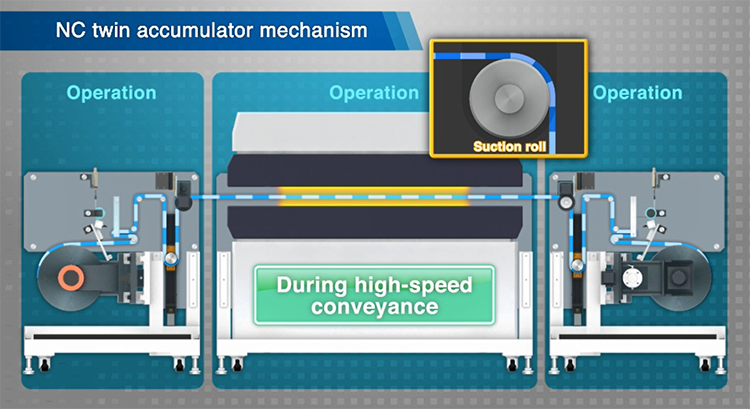

| Machine specification | Transport method | Continuous transfer / intermittent transfer |

| Continuous transfer capacity | Up to 50m / min | |

| Intermittent transfer capacity | ~900mm/0.9sec | |

| Intermittent feed pitch | ~900mm | |

| Tension value | 10N~100N |

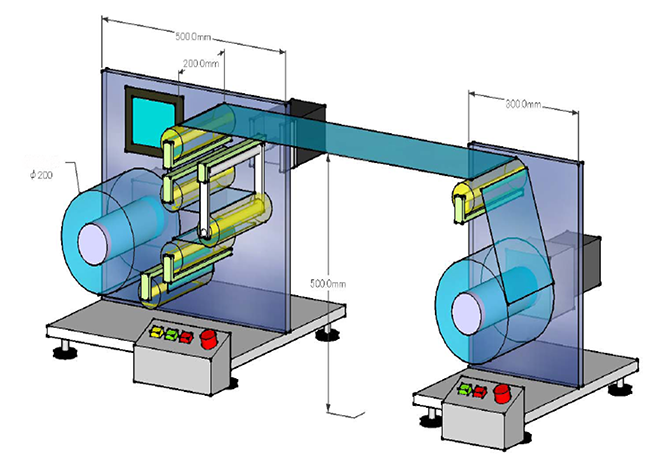

| Lab machine reference specifications | ||

|---|---|---|

| Base material specification | Base material | PET, PI, PP, PEN, PMMA, PC, TAC, COP, COF, Cu, SUS, non-woven |

| Substrate thickness | ~ 100μm | |

| Substrate width | ~ 200mm | |

| Material specification | Material (core) inner diameter | φ3inch |

| Material outer diameter | ~ Φ200mm | |

| Material weight | ~ 20kg | |

| Machine specification | Transport method | Continuous transfer / intermittent transfer |

| Continuous transfer capacity | ~ 50m/min | |

| Intermittent transport capacity | ~200mm/sec | |

| Product winding accuracy | ±0.5mm | |

| Minimum roller diameter | φ60mm | |

| Pass line height | 500mm | |

| Material fixing | Cantilever (with screw) | |

| Positioning control device (Optional) | EPC | |

| Tension value | 10-50N / full width |